Position:Home>>Products>>QS Automatic Brick production

Product description

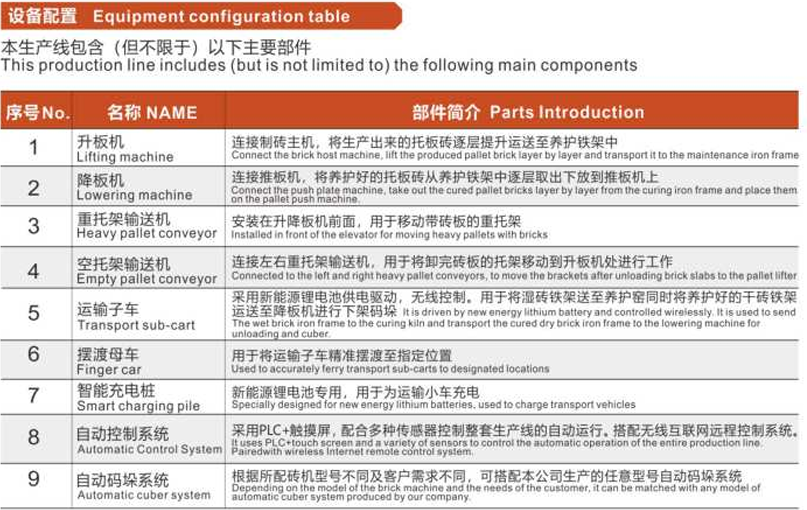

The QSDJ intelligent belt rack maintenance fully automatic production line is mainly composed of batching mixing system.prefabricated molding system, belt rack maintenance system, brick dividing and cuber system, automatic packaging systemand other system componenls, Compared with simlar foreign equipment, the equipment is more complete, the layout is morereasonable, the process route is smoother, the degree of automation is higher, and the purchase cost is low.

Process introduction

This production line is a fuly automatic production line with rack maintenance. The unique equlpment configuration can beseamlessly malched with the brick-making host of any manufacturer at home and abroad. Diflerent equipment configurationhans can be exclusively cuslomized accordino lo ihe ocalon ol the user's sle, dlerentbrick-makina hosts and the oroduclonof different products.

The wet bricks preformed in this production line are lifted up by a plate liter and placed on the iron frame. Each layer of bricks isisolated from each other, After the bricks are filled, the entire lron frame can be lransierred to the maintenance area with aorklift, lt can also be equipped with new energy intelligent finger car to transport it to the curing kiln for curing.This production line is a fully automatic production line with inlegrated control of light, machinery, electricity and llquids. it iscontrolled by a microcompuler and all componenis of the sel.-organized 485 wireless network are connected lo each otherthrough the network system. l is also equipped with a cloud network that can troubleshoot equipment faults through remolereal-time monitoring of equipment usage, solving users' worries about after-sales maintenance and debugging of equipment.